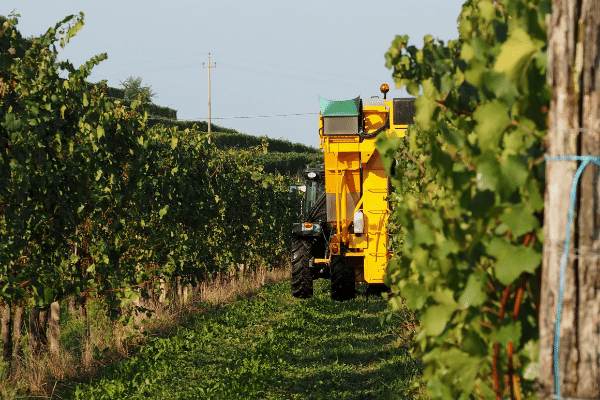

Some grape news for producers battling labor shortages in wine country: robots.

UC Davis’ new guidelines for robotic pruning, canopy management, and harvesting of wine grapes point towards a “touchless” future for viticulture. Machines can tackle pruning, leaf removal, shoot thinning, and trunk suckering, saving nearly $1 per vine in labor costs on their experimental farm.

By the numbers:

- 90% of U.S. crushed wine grapes are mechanically harvested

- Mechanical pruning can save 60-80% of labor costs per acre

- 2x the color – read: quality – was found in one study of merlot grapes

And grape growers are here for the robot revolution. They’ve long expressed concerns about labor as vineyards grow larger and workers become scarce.

Soundbite: “Our estimate is we have two-thirds less people working in wine grapes now,” said Prof. Kaan Kurtural, of UC Davis.

The pressure is on for technology like robotics, artificial intelligence, and automation to fill that labor gap. And researchers say that’s within reach – plus changes could lead to skilled, high-wage jobs for folks operating the advanced machines.

Will wine connoisseurs notice a difference? If it’s man against machine, recent advancements make it hard to tell a difference between hand-harvested and mechanically harvested grapes. However, some grapes, like Pinot Noir, require special handling and aren’t suited for mechanization.

But on the whole, mechanization makes sure there’s no wine left behind.